Thermoplastic Composites in Aerospace: Inspection Challenges and Solutions from CICNDT, the AIMM Center, and Omni NDE

From Thermoplastics to Total Integrity: Inspection Evolves

As thermoplastic composite (TPC) nacelle structures gain momentum—led by Collins Aerospace and other OEMs—Composite Inspection and Consulting (CICNDT) and the Advanced Inspection Methods and Materials (AIMM) Center are at the forefront of adapting nondestructive testing (NDT) and evaluation (NDE) to meet the demands of this evolving material frontier. With partner Omni NDE, the AIMM Center is uniquely positioned to ensure structural soundness, weld quality, and process validation for TPC components at scale.

This new era of aerospace manufacturing—favoring welded, co-consolidated thermoplastics over traditional thermosets—requires a rethinking of inspection strategies, especially for high-throughput production lines and complex geometries.

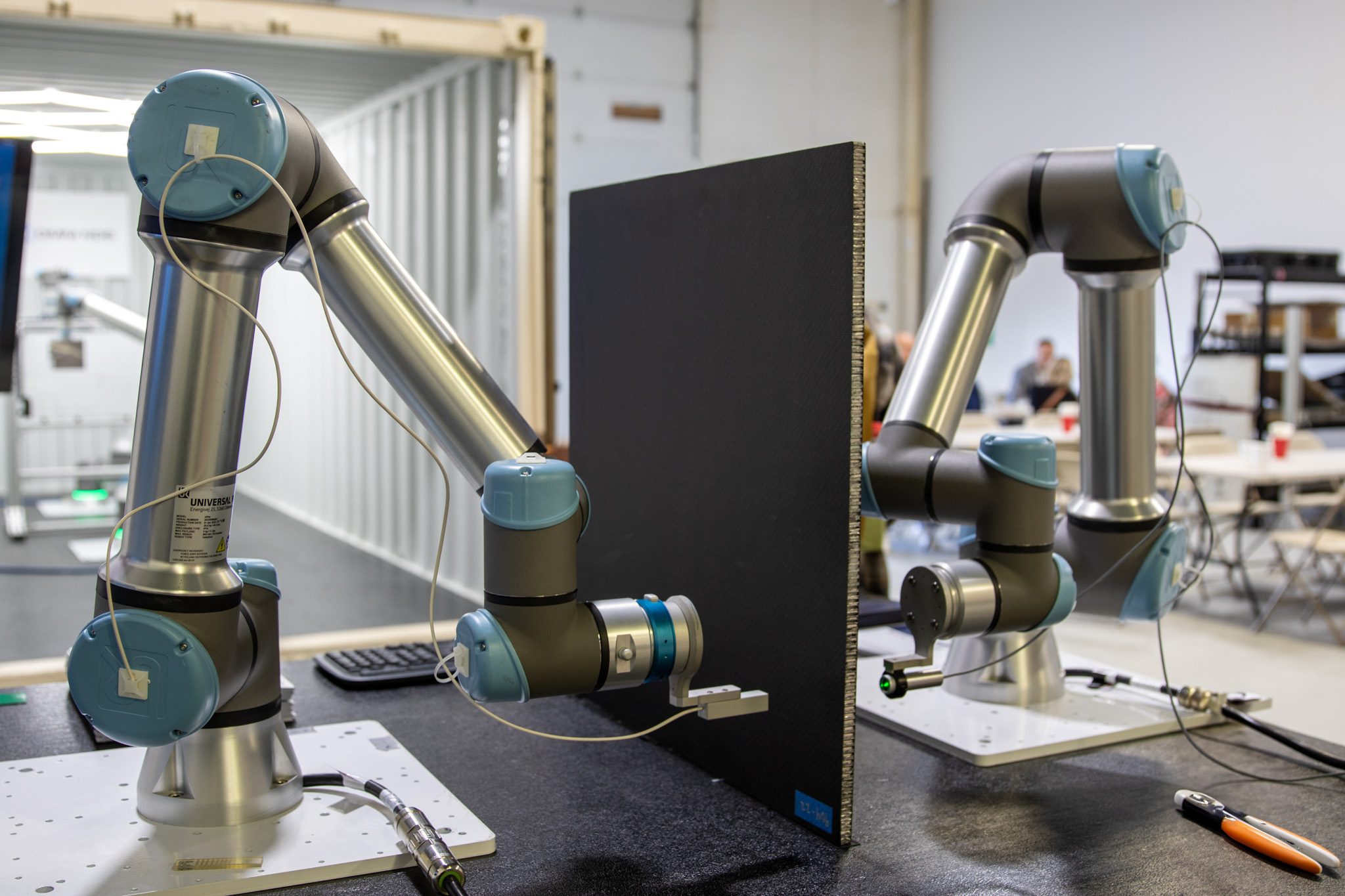

🤖 Cobot-Enabled CT: The Core of Complex Geometry Assurance

The AIMM Center has implemented Cobot-Enabled Computed Tomography (CT) systems that provide non-contact, high-resolution internal imaging of complex thermoplastic parts such as:

- Fusion-formed nacelle skins with integrated stiffeners

- Hollow hat frames and curved welded structures

- Double-contoured composite rib geometries

These CT systems, mounted on collaborative robots (cobots), adaptively inspect intricate geometries while maintaining operational safety and automation efficiency. Volumetric CT enables the detection of voids, incomplete fusion zones, and laminate inconsistencies—critical for ensuring the internal integrity of high-value aerospace components.

🌀 Laser Shearography via Dantec: Surface Defect Detection Mastery

At the AIMM Center, Laser Shearography (ST) is conducted using a series of Dantec Dynamics systems designed to rapidly identify surface strain anomalies. CICNDT/AIMM employs the Dantec FlawHunter vacuum hood system for larger production parts or components requiring deeper inspection.

Applications Include:

- Co-consolidated skins and skins with Lightning Strike Protection (LSP)

- Curved thermoplastic fan cowls and longerons

- Post-weld strain analysis for residual stress evaluation

Key Advantages:

- Real-time mapping of delaminations, debonds, and core crushes

- Full-field optical measurement—ideal for rapid throughput

- Vacuum and thermal load excitation options

- No coupling medium or consumables—suitable for painted or coated surfaces

Unlike traditional UT or tap testing, ST reveals dynamic material behavior under load, making it particularly suitable for fusion-welded thermoplastics where surface visual cues may be minimal but strain signatures persist.

🛠️ Complementary Inspection Modalities

Beyond CT and ST, the AIMM Center integrates multiple NDT techniques to create a comprehensive inspection framework:

- Ultrasonic Testing (UT):

- Phased Array UT (PAUT) for curved weld seams and thicker sections

- Air-Coupled UT for rapid scanning of large, thin-sheet TPCs

- Immersion UT for precision inspection of small or high-aspect-ratio parts

- Active Thermography:

- Pulsed and lock-in thermography for weld and bondline validation in both flat and contoured areas

- Eddy Current Testing (ECT):

- Effective for verifying LSP mesh continuity and surface crack mapping, especially post-paint or post-weld

- Laser Profilometry & Structured Light Scanning:

- Used to confirm geometrical accuracy and detect warping or inconsistencies in consolidation-stamped components

🧪 Integrated Process Intelligence

With Scan-as-a-Service (SaaS) capabilities, the AIMM Center provides vital support to manufacturers such as Collins Aerospace through:

- Rapid prototype assessment of TPC weld interfaces

- Development of custom robotic inspection paths for non-standard geometries

- Weld and bond qualification aligned with aerospace compliance standards (AMS, NADCAP)

- Full data traceability to support audits and certification

✈️ From Thermoplastics to Takeoff: Your Inspection Partner

As aerospace OEMs like Collins scale their use of high-rate thermoplastic manufacturing, the AIMM Center—leveraging CICNDT’s consulting and Omni NDE’s integration expertise—ensures every component not only meets structural requirements but exceeds expectations for readiness and safety.

With robotic CT systems, Dantec’s Shearography (ST) solutions, and a broad array of process-matched NDT modalities, AIMM is enabling the next generation of aerospace thermoplastics to take off with confidence, precision, and integrity.